2023 Finalists: The Engineer - Collaborate to Innovate awards

This prestigious award was established to uncover and celebrate great examples of technology-led engineering collaboration across a range of different disciplines and sectors.

✨This year the Midlands Centre for Data-Driven Metrology has been shortlisted in the field of Manufacturing Technology with the work: A single-click automated manufacturing metrology demonstrator

Consortium of collaborators:

- Manufacturing Metrology Team (MMT) (Faculty of Engineering, University of Nottingham).

- The Nottingham Advanced Robotics Laboratory (NARLy). The Advanced Manufacturing Technology Research Group (Faculty of Engineering, University of Nottingham).

- Intelligent Automation Centre (Loughborough University).

- Institute for Advanced Manufacturing and Engineering (Coventry University).

►Collaborative research is at the heart of the project “A single-click automated manufacturing metrology demonstrator” and internal and external collaborations are essential to its success. The optical demonstrator of this work is one of the primary activities of the Midlands Centre for Data-Driven Metrology (MCDDM) focused on transferring knowledge from academia to industry through translational research and dissemination. The project has benefited from insights of industrial partners and interactions with Small and Medium-sized Enterprises (34 SMEs between 2021-2023) that have contacted the MCDDM looking for support in digital manufacturing and new inspection technologies.

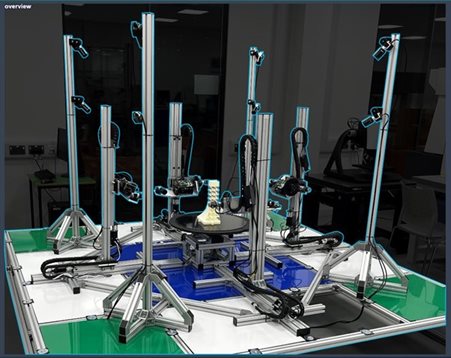

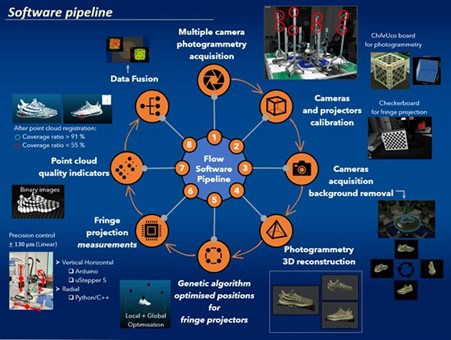

► In the MMT and NARLy, the project's success has been bolstered by different mindsets, expertise,and perspectives. Leadership is highly collaborative and genuinely managed under the supervision of Professor Samanta Piano in the field of manufacturing metrology, Professor Peter Kinnell in the field of metrology and industrial automation, Professor Marcos Kauffman in digital twins implementation, and Professor David Branson in the field of dynamics and controls. The technical project is managed by Dr LukeTodhunter (Centre Manager). Dr Adam Thompson has led the mechanical design ofthe overall demonstrator along with the installation of hardware (stage completed).Dr Mojtaba A Khanesar (NARLy) and Dr Francisco Ulises Hernandez Ledezma (MMT) lead the software programming for precise motion control of linear and rotational stages. Dr Luke Todhunter (MMT), Dr Sofia Catalucci (MMT) and Dr Francisco Ulises Hernandez Ledezma (MMT) lead the software integration pipeline with open-source code in python and MATLAB: fast multiple camera acquisition with python wrappers; multiple camera calibration, camera position optimisation, 3D photogrammetry reconstruction, fast custom-made fringe projection code and point cloud quality analysis. The project has benefited from collaborative work of PhD students within the MMT: Mingda Harvey Yang has deployed machine learning and machine vision algorithms to optimise photogrammetry 3D reconstruction and Michael (Zhongyi) Zhang has developed novel data fusion algorithms for point cloud registration. External collaborations and synergies with the research group of Professor Marcos Kauffman and Dr Glen Turley (Coventry University) is further enhancing the capabilities of the advanced optical demonstrator to include digital twins and why they are important in Metrology. Similarly, collaborations with Loughborough University and Professor Peter Kinnell brings to the project capabilities with the use of machine learning for defect detection and high-resolution inspection of large complex parts used in industry sectors such as the construction or aerospace.

Future steps in this project consider collaborating with providers of inspection instruments and incorporating these devices mounted on collaborative robots. This integration will contribute an additional layer of expertise to the project's capabilities, enabling the demonstrator to be benchmarked against other commercial products. In conclusion, the knowledge, and insights from the three university partners is leading this demonstrator project to the development of novel measurement methodologies and data analysis techniques that leverage the strengths of 3D coordinate metrology measurements, speed, and automation in digital manufacturing.

>> Shortlisted entries will be judged by a panel of some of the UK’s leading engineers, and the winners will be announced on Thursday 29th February 2024 at a special awards party at One Great George Street, London.